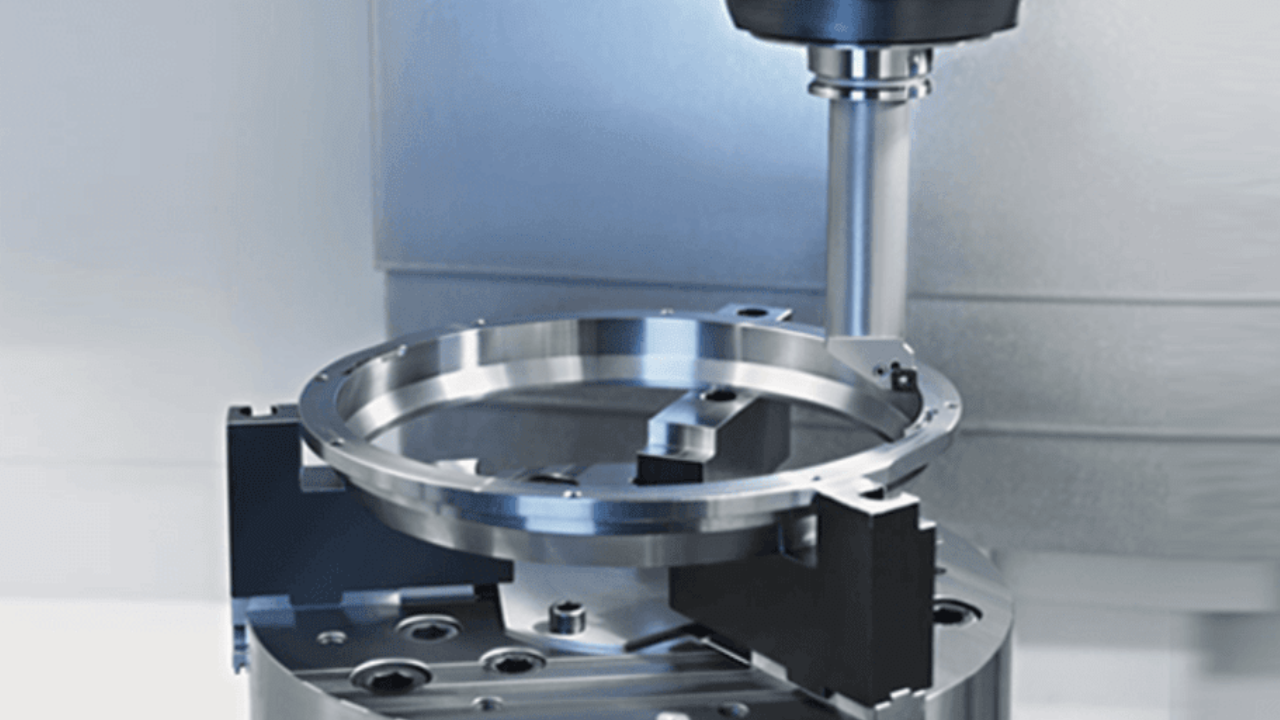

Computer Numerical Control (CNC) machining is a production process that uses programming and digital controls to run precise machinery. It allows for the highly accurate and efficient manufacture of parts and components by replacing conventional manual processes. In CNC machining, cutting tools, and other machinery are moved using an automated system that reads design specifications and translates them into numerical code.

Metals, polymers, and composite materials can all be processed using this method. Intricate and sophisticated designs are made possible by cnc machining, which includes mills, lathes, and routers. These machines are used in a variety of industries, including electronics, aerospace, and medicine. CNC machining has become an essential component of contemporary manufacturing.

Kinds Of Cutting Tools Are Frequently Utilized In CNC Machining

We can delve into the not unusual kinds of cutting tools utilized in CNC machining, exploring their characteristics, applications, and contributions to the manufacturing manner.

End Mill

Give-up turbines are perhaps the most ubiquitous cutting tools in CNC machining. They arrive in numerous sizes and styles, each designed for precise packages. General give-up mills are characterized by a cylindrical shape with slicing edges on each the give-up face and the perimeters. Ball nose cease turbines, on the other hand, have a rounded cease, best for contouring and 3-D machining. Flat cease mills are suitable for general milling tasks, whilst nook radius end generators provide expanded power in corners.

Drill Bits

Drill bits are important for creating holes in workpieces. In CNC machining, drill bits come in diverse kinds, which include twist drills, center drills, and notice drills. Twist drills are the most unusual, with a helical flute layout that aids in chip evacuation. Middle drills are used to create a starting point for large drills, at the same time as spot drills are employed to create a particular indentation for the next drill.

Milling Cutters

Milling cutters are versatile equipment that can perform more than a few machining operations. They encompass face mills, which have cutting edges on the outer edge and the face, and slab mills, designed for casting off big quantities of material. T-slot cutters are specialized milling cutters used for growing T-fashioned slots in workpieces, typically discovered in fixture design.

Turning Equipment

In CNC turning, wherein the workpiece rotates whilst the cutting tool remains desk-bound, turning gear are paramount. This equipment includes inserts with diverse geometries, which include square, round, or triangular, relying on the favored slicing operation. Moreover, parting and grooving tools are hired to cut off sections of the workpiece or create grooves with precision.

Inserts

Inserts are replaceable slicing recommendations that match a holder or tool body. They’re designed for particular materials and cutting situations. Carbide inserts are famous due to their hardness and resistance to wear. Coated inserts, along with people with titanium nitride (TiN) or other coatings, beautify tool existence and overall performance.

Reamers

Reamers are used to refine the diameter and surface end of pre-drilled holes. They arrive in diverse designs, together with straight-fluted, spiral-fluted, and helical-fluted reamers. Spiral-fluted reamers are mainly powerful for chip evacuation during the reaming method.

Broaches

Broaches are specialized cutting gear used for machining complex shapes and contours. CNC machines ready with broaching competencies can create keyways, splines, and other complex capabilities. Inner broaches are designed for interior contours, at the same time as outside broaches are used for outer profiles.

Thread Mills and Taps

For creating threads in CNC machining, thread turbines, and faucets are generally used. Thread generators are versatile and may produce threads of various sizes, even as taps are used for growing inner threads. Each piece of equipment is available in one-of-a-kind designs, including straight-fluted, spiral-fluted, and helical-fluted, relying on the utility.

Chamfer Generators

Chamfer generators are designed to create chamfers or beveled edges on the workpiece. They are important for reinforcing the aesthetics of an aspect and can also be used to cast off sharp edges that are probably at risk of strain concentrations.

Conclusion

A wide variety of cutting tools are used extensively in the field of CNC machining to form raw materials into complex and accurate components. Every tool used in machining, from drill bits and end mills to broaches and turning tools, has a distinct function. Cutting tools for CNC systems will advance along with the technology, pushing the limits of precision and productivity in manufacturing.